Pallets should be un-treated and stored under-cover to keep them dry.

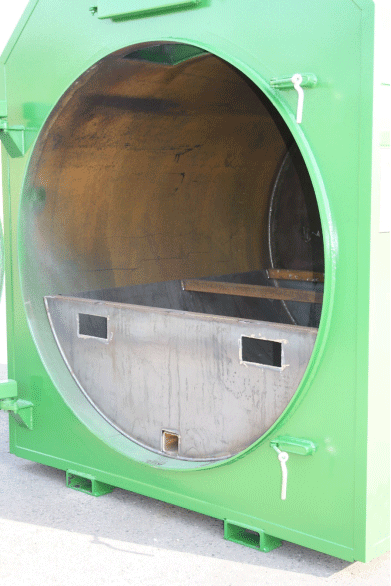

They can be loaded into the dragon using a forklift.

One 17 kg pallet will produce approx 60 kW of energy. Therefore a 240 kW D240 will burn for approx 3 hours when loaded with 12 pallets.

There are strict rules for burning waste wood in Dragon Biomass Boilers.

Please contact us for more information. Alternatively, go to the Environmental Agency web site and to your local authority. If you would like to burn waste wood in an approved appliance such as a Dragon, please contact us and we can advise on boilers that can burn full pallets or shredded wood.

We have several ways of loading waste wood and arborcultural waste into a Dragon.

For example, our cartridge system involves loading a cartridge full of broken wood and loading it into the boiler with a forklift.

We can also supply baskets for loading into the Dragon